Product News

Product development is a continuous process at Weddle Industries. Our design team is constantly searching for ways to make things stronger, function better or easier to install.

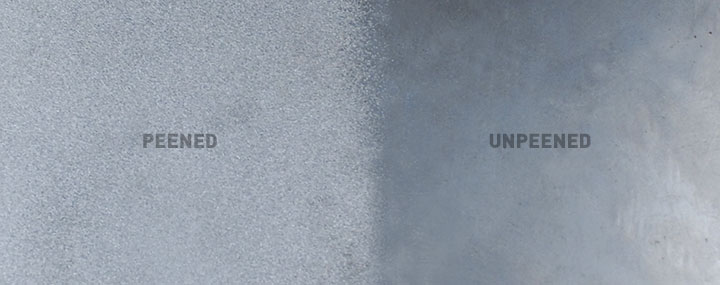

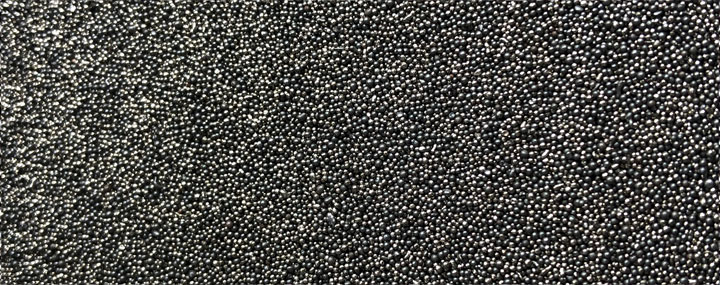

Shot peening is a process in which hardened media called “shot” is used to bombard the surface of a metal part. This effectively hammers the part with thousands of small metal balls, which dimple, or “peen” the surface.

Why is this necessary? When metal components are manufactured, they go through various hot and cold metal working processes, including rolling, forging, bending, machining, heat treatment, and grinding. These processes leave the surface of the manufactured components in tension. If this tension is not relieved, cracks will tend to form, which can lead to component failure. An analogy we use here in the shop is a tight t-shirt versus a loose t-shirt. A tight shirt that is snug is more likely to tear than a loose shirt that just hangs. Peening creates a “loose” surface (a surface in compression) is much less likely to crack than a tight surface in tension.

A proven and effective way to reduce surface tension, and is used in many industries to extend the life of critical components. Because the overlapping dimples from shot peening leave the surface of a component in compression, rather than in tension, surface cracks are much less likely to form, and the risk of failure due to crack propagation is greatly reduced.

Shot peening is an important part of what we do at Weddle Industries. All Weddle Racing gears, ring and pinions, input shafts, heavy duty slider hubs, and many of our other high-end components, are fully shot-peened as part of the manufacturing process. For components that were not originally shot peened (such as stock gears), we have in-house shot peening capability to help make them more suitable for use in high-performance applications. Please call for details.

Questions? Call us at 805 562 8600 or email us.