Product News

Product development is a continuous process at Weddle Industries. Our design team is constantly searching for ways to make things stronger, function better or easier to install.

Detect cracks and wear before they can take you out of a race. In any race car, driveline components are exposed to extreme shock loads. Cracked components are a fact of life.

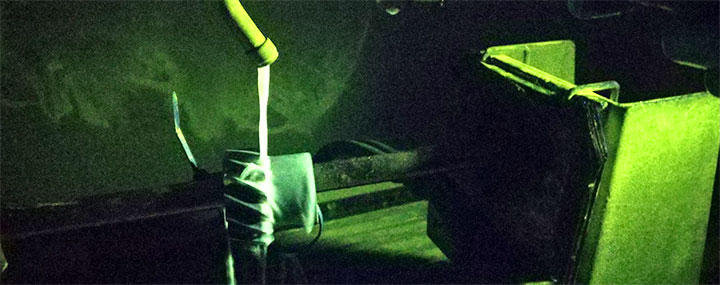

Checking driveline components for cracks is an essential part of any thorough race car prep. Our Magnaflux wet bench inspection unit has allowed us to spot problems before they turn into disasters. It has been essential in informing our design changes and helps us improve gear and service life.

How it works. First discovered in the 1920's, the Magnaflux process works like this: the components (made of ferrous material) are first bathed in a solution of special iron oxide particles. When the components are subjected to a magnetic field, a high concentration of magnetic flux around surrounds any surface imperfection. These imperfections can be made visible by exposing them to UV light. If it is determined that the imperfection is a crack, the part is marked accordingly and set aside for further visual inspection.

We use the Magnuflux process to inspect forward gears, ring and pinions, input shafts, shift mechanism, differential components, drive stubs, axles, CV joints, and much more. The top drivers rely on this to give them an efficient and accurate inspection of their driveline components.

Questions? Call us at 805 562 8600 or email us.